Archive

- All posts

- September, 2025 (1)

- August, 2025 (1)

- July, 2025 (1)

- July, 2025 (1)

- June, 2025 (1)

- June, 2025 (1)

- June, 2025 (1)

- June, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- May, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- April, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- March, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- February, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- January, 2025 (1)

- 2024 (1)

-

0 Smart Gas Stations with AI & IoT – Florida Petroleum Innovation

- Petroleum Contractors

- by Jeffrey Burke

- 9-1-2025

5.00 of 111 votesGas Station of the Future: AI, ML & IoT Innovations in Florida Fuel Retail Imagine fueling up not only to gas up—but to experience a smart, responsive, and almost futuristic service. Florida’s fueling industry is evolving fast, thanks to AI, machine learning (ML), and the Internet of Things (IoT). From predictive maintenance to dynamic fuel pricing, here's how these technologies are redefining convenience for customers and efficiency for operators. 1. Real-Time Monitoring & Predictive Maintenance Sensors and IoT-enabled devices embedded in pumps, tanks, and dispensers can stream performance data continuously. AI models analyze anomalies—like wear patterns or temperature shifts—before they escalate into failures. Predictive maintenance means fewer unexpected breakdowns and more uptime. ([arxiv.org](https://arxiv.org/abs/2504.13976?utm_source=chatgpt.com)) 2. Dynamic Pricing & Personalized Offers Florida’s fuel prices fluctuate—weather changes, demand peaks, and local events all play a role. By combining ML insights with regional data, stations can adjust pricing in real-time, offering promotions based on patterns like your car’s purchase history—or surge pricing during high-demand periods ensuring smarter margins and happier customers. 3. Automated Inventory & Smart Payment Systems IoT-connected storage, delivery logistics, and inventory sensors automatically flag low-stock thresholds and reorder fuel before you're empty. At the pump, AI-driven systems (think IoT-enabled kiosks or contactless facial recognition) streamline payment, reducing lines and speeding up the fueling experience. 4. Enhanced Safety & Compliance via AI Oversight Whether dealing with vapor intrusion, spill detection, or compliance issues, smart networks can flag risks immediately. Cameras with AI can observe leaks or unsafe behaviors and automatically shut down systems or notify operators—critical for Florida’s regulatory environment and emergency readiness. 5. Energy Integration & Environmental Efficiency Next-gen stations combine solar-powered lighting, smart HVAC systems, and AI-optimized energy use. Tech-enhanced stations reduce energy costs, boost green credibility, and often meet or exceed environmental mandates—essential in a state like Florida with high sustainability visibility. Why Florida Needs Smart Fuel Retail With heavy tourism, regional weather disruptions, and growing demand, Florida’s gas retailers benefit from agility. Faster pump times, fewer outages, and proactive pricing give operators a competitive edge—while giving consumers a sleeker, high-tech experience that feels truly future-ready. The future of fueling isn't a distant vision—it’s arriving now. Whether it’s cost-saving automation, safer system alerts, or seamless payment by the pump, these technologies deliver real ROI. Ready to bring AI, ML, and IoT into your fuel site? Let’s build smarter, safer, and faster fueling together—reach out and let’s future-proof your pumps.

-

0 Turnkey Fuel System Construction in Florida: Full-Service Fueling Solutions

- Petroleum Contractors

- by Jeffrey Burke

- 8-1-2025

5.00 of 91 votesTurnkey Fuel System Construction in Florida: What to Expect When you're building or upgrading a fuel site in Florida, the turnkey fuel system construction approach provides peace of mind—and a finished, fully operational fuel system—without the usual headaches. Here's what to expect and how a trusted Florida petroleum contractor ensures every step is handled, from concept to first pour. 1. Concept & Engineering Design Your journey starts with a full design phase. A qualified team will survey your location, evaluate codes and environmental requirements, and develop a plan that covers everything—from underground storage tank (UST) or aboveground storage tank (AST) placement to canopy layout, pump islands, dispensers, and control systems. This approach ensures all components work seamlessly together and meet local building standards. 2. Permitting & Regulatory Compliance Florida has strict permitting rules for fuel systems, especially within municipalities and environmental territories. A turnkey provider takes care of submitting permit applications, coordinating with regulatory agencies, and ensuring compliance from DEP, city zoning, to fire codes. This removes bottlenecks—so nothing halts your construction's forward motion. 3. Site Work & Tank Installation Once approvals are in hand, site prep begins. Expect grading, trenching, and excavation for tanks and piping. Licensed technicians install USTs or ASTs, set up piping networks, and coordinate delivery of materials and cranes if needed. This seamless process ensures tanks are correctly positioned and tied into your system’s plumbing infrastructure. 4. Canopy, Dispenser & Equipment Setup With the utilities in place, construction moves to above-ground elements: pouring concrete pads, erecting the canopy, and setting up fuel dispensers, shear valves, hoses, and nozzles. Every piece—Veeder‑Root gauges, spill containment, vapor recovery—is positioned and connected by factory-trained technicians to meet manufacturer specs and safety standards. 5. System Commissioning & Quality Assurance After installation, the system isn't simply turned on. A rigorous commissioning process ensues, including leak tests, dispenser calibration, and gauge system checks. This phase confirms everything—from vapor systems to piping integrity—functions properly and safely under real‑world conditions. 6. Training & Turnover A true turnkey experience includes client training. New owners and staff receive instruction on daily operations, routine checks, and emergency procedures—ensuring your team can confidently manage and maintain the new fuel system. 7. Follow‑Up & Support Even after handoff, a quality turnkey contractor offers ongoing support—think scheduled inspections, compliance audits, and service plans for preventive upkeep. You’ll have a single trusted point of contact for any future upgrades or repairs. Why Turnkey Matters in Florida Florida’s regulatory environment, weather patterns, and development requirements make turnkey projects especially beneficial. You bypass licensing hurdles, reduce coordination through a single contractor, and avoid hidden delays. Plus, your investment delivers faster ROI—getting your pumps open sooner, legally and safely. If you're ready to take the stress out of building or upgrading your fueling site—from permits to pumps—reach out to us today. We handle every detail, so you're open for business on time and fully compliant.

-

0 EPA‑Compliant Storage Tank Installation & Replacement in Florida

- Petroleum Contractors

- by Robert Wood Jr

- 7-1-2025

5.00 of 107 votesEPA‑Compliant Storage Tank Installation & Replacement in Florida If you're planning a fuel site project in Florida, ensuring EPA-compliant storage tank installation or replacement is essential for environmental safety and legal peace of mind. In the Sunshine State, this means navigating complex permitting, installation, and testing protocols—so you avoid liabilities and expensive shutdowns. Here’s how our expert petroleum contractors handle every essential step to ensure your system is compliant, protected, and built for longevity. 1. Thorough Permit Acquisition & Regulatory Strategy EPA, DEP, and local jurisdictions each have their own requirements for UST (Underground Storage Tank) and AST (Aboveground Storage Tank) projects. A top-tier contractor guides you through every license application, site assessment, and documentation step—ensuring your tanks meet federal, state, and local standards before a shovel hits the ground. 2. Expert Tank Removal & Soil Remediation Replacing an old or non-compliant tank requires safe removal. Our teams conduct all UST removals in accordance with EPA’s 40 CFR Part 280 requirements. They also ensure careful handling—even undertaking soil sampling or remediation if contamination is present—to safeguard environmental health and property value. 3. Precision Installation of EPA-Approved Tanks Installation isn’t just about lowering a tank into the ground. Our contractors install double-wall, leak-detection-compatible USTs or steel/UL-certified ASTs—complete with secure piping, backfill, leak sensors, and spill containment, all in accordance with EPA and NFPA codes. 4. Leak Detection Systems & Safety Redundancies Modern systems deploy continuous monitoring—such as automatic tank gauging and leak detection—to catch issues early. We integrate sensors, alarms, and automatic shutoffs into each tank installation, ensuring a faster response and minimized environmental risk. 5. Commissioning, Compliance Checks & Documentation With installation complete, we conduct pressure testing, interstitial monitoring, cathodic protection checks (if applicable), and final inspections. Our operational checklists and compliance reports are delivered so you can confidently demonstrate adherence to EPA and state mandates. 6. Maintenance Training & Responsive Support A compliant tank is only safe if maintained. We train your staff on essential upkeep—like running monthly line checks, inspecting spill buckets, and understanding tank monitoring reports. Plus, we offer responsive service plans for calibration, repairs, and regulatory audits. Why EPA Compliance Is a Game Changer In Florida, environmental risk isn’t hypothetical—it’s real. EPA-compliant tank systems minimize groundwater contamination and fines, simplify insurance, and boost reliability. And by trusting a licensed and experienced contractor, you gain control, save on costly delays, and get peace of mind in every stage. Your fuel infrastructure is only as strong as your tank. Let’s build it right from Day One—design, install, inspect, and support—all with EPA standards at the core. Ready to get started? Drop us a message and we’ll craft your permit-to-pump solution with confidence.

-

0 Turnkey Fuel System Construction in Florida: Full‑Service Fueling Solutions

- Petroleum Contractors

- by Jeffrey Burke

- 6-1-2025

5.00 of 101 votesEPA‑Compliant Storage Tank Installation & Replacement in Florida When it comes to installing or replacing storage tanks in Florida, EPA compliance isn't optional—it’s essential. Our expertise ensures your UST (Underground Storage Tank) or AST (Aboveground Storage Tank) project is safe, code-compliant, and stress-free from permitting to pump activation. 1. Navigating EPA & DEP Regulations Florida enforces strict regulations for storage tanks. We manage everything—from initiating a compliance roadmap aligned with federal (EPA) guidelines to securing DEP and local permits—so your project launches without environmental or legal setbacks. 2. Safe Removal of Old Tanks Decommissioning or upgrading your tank requires secure removal. We conduct proper UST/AST removal, site soil assessment, and environmental remediation when needed—completing required documentation for final closure with regulatory bodies. 3. Installing EPA-Approved Tanks Your new tank system features best-in-class equipment: double-wall construction, anti-corrosive systems, leak detection sensors, and spill containment. We build to NSPS and NFPA standards, with full shielding and monitoring systems. 4. Precision Testing & Commissioning Installation isn’t complete without commissioning. Our team runs pressure testing, interstitial monitoring, and leak detection checks to ensure everything works under operational conditions—precisely calibrated and compliant. 5. Empowering Training & Long-Term Support After installation, we train your team on system operation, inspection routines, and emergency protocols. Staying compliant requires vigilance—so we offer regular service plans, tank audits, and regulatory updates to keep you on track. Why EPA Compliance Matters in Florida Non-compliant tank installations risk environmental hazards, legal fines, and operational downtime. By choosing an EPA-focused approach, you gain cleaner operations, stronger insurance options, and peace of mind from Clearwater to Miami. Ready for a worry-free, EPA-compliant tank solution that prioritizes safety, regulation, and reliability? Let’s build something that lasts—fuel infrastructure done right. Reach out today for a straightforward, compliant installation process.

-

0 Routine Fuel System Maintenance & Upgrades in Florida

- Petroleum Contractors

- by Robert Wood Jr

- 5-1-2025

5.00 of 98 votesRoutine Fuel System Maintenance & Upgrades in Florida In Florida’s dynamic environment, maintaining peak performance and safety of your fuel system is essential. From corrosion risks in humid coastal climates to evolving regulations, our comprehensive fuel system maintenance and upgrade services help your business avoid downtime, fines, and costly repairs—while keeping your infrastructure future-proofed and operationally sound. 1. Scheduled Preventative Maintenance A routine check-up for your fuel system goes a long way. We provide monthly and annual inspections—covering line tightness, dispenser calibration, spill bucket integrity, and pressure-tested piping—to catch small issues before they escalate. 2. Veeder‑Root & Gauge System Testing Automated fuel monitoring devices like Veeder‑Root are the backbone of modern fueling systems. We perform calibration, leak detection checks, and system diagnostics to ensure your alerts trigger when needed—and not too late. 3. Dispenser Retrofits & Pump Modernization Upgrading your fueling islands can greatly improve efficiency and ROI. We retrofit older dispensers with newer hoses, nozzles, and flow meters—or install entirely new units with touchscreen controls, contactless payment, and enhanced security features. 4. Piping, Nozzle, & Accessory Replacements Worn hose assemblies, aging shear valves, and obsolete fittings can cause leaks or service interruptions. We replace these components proactively, using quality parts designed to meet Florida codes and withstand local environmental stressors. 5. Compliance Audits & Reporting Stay ahead of regulatory requirements with our compliance audits. We assess your system against DEP and EPA standards, document results, and make tailored recommendations—so you’re always inspection-ready. Why Ongoing Maintenance Pays Off in Florida Florida’s precipitation, humidity, and stringent environmental rules pose unique long-term risks to fueling infrastructure. Scheduled maintenance and timely upgrades reduce risk, extend equipment life, minimize liability, and keep your pumps operational—especially during peak business seasons or before hurricane events. Consistent service is proactive protection. Fuel infrastructure isn’t “set it and forget it”—it needs strategic care and smart upgrades. Let us tailor a service plan that protects your investment and keeps your pumps running smoothly, even under the Florida sun. Get in touch today to schedule your next maintenance visit and upgrade consultation.

-

0 Fuel Station Retrofits: Boost Efficiency Without Full Rebuild

- Petroleum Contractors

- by Jeffrey Burke

- 4-1-2025

5.00 of 110 votesFuel Station Retrofits: Improving Efficiency Without a Full Rebuild Sometimes, a complete rebuild isn’t necessary to bring your fuel site up to performance standards. With smart retrofits, you can modernize your station, improve safety, and stay compliant—without the disruption or cost of ground-up construction. Here's how tailored retrofit services can revitalize your fueling infrastructure. 1. Dispenser & Veeder‑Root System Upgrades Outdated dispensers and monitoring systems can impact efficiency. Upgrading to newer models and calibrating devices like Veeder‑Root ensures accurate metering, improved fuel flow, and better detection of leaks—keeping you compliant and responsive. 2. Hose, Nozzle & Shear Valve Replacements Routine wear-and-tear on hoses, nozzles, and shear valves can lead to leaks or inefficiency. Swapping in newer, code-compliant components helps maintain safety and preserves fuel integrity—often with minimal downtime. 3. Leak Detection System Enhancements Early detection of leaks is critical. Advanced systems like Memory-based Online Change Point Detection (MOCPD) offer real-time alerts for leakage—alerting you to anomalies faster than traditional methods. :contentReference[oaicite:1]{index=1} 4. Preventive Maintenance as You Retrofit Combining retrofits with routine checks—not just on the visible elements, but also spill buckets, sump seals, and line fittings—ensures the whole station benefits from improved safety and durability. Consistent inspection is the bedrock of lasting upgrades. :contentReference[oaicite:2]{index=2} 5. Phased Retrofits = Minimal Disruption You don’t have to shut down your station. A phased retrofit—updating one dispenser bay or component group at a time—keeps fuel flowing while system upgrades occur in the background. It’s disruption reduction with maximum ROI. Why Retrofits Make Sense in Florida Florida’s market demands agility—weather-related cycles, regulatory updates, and intense competition. Retrofits offer a speedy way to stay ahead: lower costs, faster turnaround, less downtime, and compliance, made possible by working with experienced local petroleum contractors. No need for full demolition when a smart upgrade will do. Let’s retrofit your fuel site for better safety, efficiency, and reliability—without taking it offline. Chat with us today, and we’ll tailor a retrofit plan that suits your budget and schedule.

-

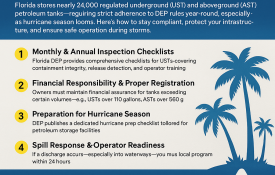

0 Florida Storage Tank Compliance & Hurricane Prep Guide

- Petroleum Contractors

- by Jeffrey Burke

- 3-1-2025

5.00 of 102 votesFlorida Storage Tank Compliance & Hurricane Preparation Guide Florida stores nearly 24,000 regulated underground (UST) and aboveground (AST) petroleum tanks—requiring strict adherence to DEP rules year-round, especially as hurricane season looms. Here’s how to stay compliant, protect your infrastructure, and ensure safe operation during storms. 1. Monthly & Annual Inspection Checklists Florida DEP provides comprehensive checklists for USTs and ASTs—covering containment integrity, release detection, and operator training. Regularly following these checklists keeps your site inspection-ready and helps prevent leaks or regulatory violations. 2. Financial Responsibility & Proper Registration Owners must maintain financial assurance for tanks exceeding certain volumes—e.g., USTs over 110 gallons, ASTs over 550 gallons. This ensures there are funds on hand for leak remediation or third-party damages. Exemptions exist but require proper oversight. 3. Preparation for Hurricane Season The DEP publishes a dedicated hurricane prep checklist tailored for petroleum storage facilities. It covers securing containment areas, shutting off emergency systems, removing spill materials, and ensuring proper discharge plans are in place. 4. Spill Response & Operator Readiness If a discharge occurs—especially into waterways—you must contact your local program within 24 hours, notify the state watch office, and begin investigations within two weeks. It’s critical to train staff ahead of time on incident notification protocols. Why This Matters in Florida Non-compliance isn't just a legal issue—it's an environmental and financial risk, and during hurricanes, the stakes are even higher. Adhering to DEP guidelines protects your community, avoids costly penalties, and keeps doors open even after severe weather. Strong compliance and pre-storm planning aren’t optional—they’re essential. Let us help you stay DEP-aligned, organized, and hurricane-ready—so your tanks are safe, secure, and operational, staff are confident, and your site weathers any storm. Send us a message and let's make your fuel site storm-proof.

-

0 Turnkey Marina Fueling Systems FL – Safe, Efficient Vessel Refueling

- Petroleum Contractors

- by Jeffrey Burke

- 2-1-2025

5.00 of 84 votesMarina Fueling System Construction in Florida: Safe, Efficient, and Compliant Florida’s coastal and waterfront environments demand specialized fueling systems. Our **marina fueling system construction** services deliver precise, safe, and efficient solutions tailored for vessels and waterfront operations—ensuring your marina meets industry standards and delivers seamless service for every boater. 1. Custom Design & Site-Specific Engineering Building marina fueling infrastructure requires more than a copy-paste approach. We tailor systems to your marina’s needs—whether it’s a small vessel dock or mega-yacht fueling station. With extensive experience designing systems for marinas across Florida, our engineering team aligns layout, piping, and fueling speeds to your unique location and service capacity. 2. High-Speed Fueling Capabilities Some marina customers need fast turnarounds during peak boating hours. We integrate high-speed fueling technology—capable of delivering over 100 gallons per minute—ensuring quick refills without spill risk or disruption. 3. Regulatory Compliance & Environmental Safety Marinas require adherence to federal, state, and coastal standards—especially regarding fuel containment, spill response, and pollution prevention. We use UL‑971 listed piping and corrosion-resistant materials for durability and safe operation within marine environments. 4. Turnkey Execution for Stress-Free Delivery From permit acquisition to final commissioning, we manage every phase. As design-build specialists, we streamline construction, reduce delays, and deliver ready-to-use marina fueling systems—so you don’t have to coordinate multiple vendors. 5. Ongoing Service & System Longevity Our support doesn’t end at installation. We offer servicing, calibration, inspections, and emergency repairs—keeping your marina fueling infrastructure safe, efficient, and compliant—even through Florida’s harsh coastal weather and high vessel traffic. Why Choose Specialized Marina Fueling Construction? Marina fueling isn’t the same as land-based station work. Saltwater corrosion, vessel safety, environmental sensitivity, and space constraints require informed precision. Choosing a contractor with experience ensures longevity, safety, and customer trust in your marina amenities. Want to elevate your marina's fuel service? We build fueling docks that are fast, safe, and fully compliant—designed for smooth operations and exceptional reliability. Let’s set up fuel solutions that keep your boats moving and your marina thriving. Reach out to us and let’s design your marine fueling future.

-

0 Marina Fueling Safety & Regulatory Best Practices in Florida

- Petroleum Contractors

- by Robert Wood Jr

- 1-1-2025

5.00 of 104 votesMarina Fueling Safety & Regulatory Best Practices in Florida Marinas are vital coastal hubs—but with fuel comes risk. Following **safety and regulatory best practices for marina fueling** not only protects your customers and environment—it keeps you compliant with Florida DEP standards and builds trust among boaters. 1. Secure Storage & Regulated Fuel Systems Florida DEP mandates USTs over 110 gallons and ASTs over 550 gallons meet stringent construction and containment requirements. These include approved equipment, leak detection, double-walled piping, spill containment, and anti-siphon valves for over-water and dock structures. :contentReference[oaicite:1]{index=1} 2. Automatic Shut-offs & Spill Prevention State regulations require fuel facilities at marinas to be equipped with automatic shut-off valves and sufficient spill containment to prevent pollutants from entering waterways when fueling systems are active. Personnel must be trained to manage spills, and systems need to be secured when unattended. :contentReference[oaicite:2]{index=2} 3. Clean Marina Environmental Best Practices Minimize risk by installing oil/water separators, using absorbent pads for bilges, and ensuring clean disposal of fouled materials. Educate boaters: discourage bilge discharge with detergents, use proper pump-out protocols, and promote preventative maintenance. :contentReference[oaicite:3]{index=3} 4. Boater Education & Staff Training Fueling is only as safe as the people behind it. Train fuel dock staff with resources like BoatUS’s spill prevention course and provide clear signage to guide safe fueling behavior. :contentReference[oaicite:4]{index=4} 5. Operational Monitoring & Recordkeeping Routine checks—monthly or during fueling shifts—help catch leaks early and maintain system integrity. Florida DEP regulations require documentation retention (e.g., monthly inspections, maintenance records) and operators must understand incident response protocols. :contentReference[oaicite:5]{index=5} Why Safe and Compliant Fueling Matters in Florida Florida’s coastal ecosystems are fragile—and silty fuel spills can harm marine life, coral reefs, and water quality. Adhering to safety rules, fostering staff and boater awareness, and building with best practices safeguards both nature and operations. Fueling boats safely isn't just a requirement—it's a commitment. Let us help your marina thrive with compliant, protected, and confident fueling operations. Ready to elevate your fueling standards? Reach out, and we'll guide you through every step with care and compliance in mind.

-

0 Mobile Fuel Delivery in Florida: Convenience Meets Rapid Market Growth

- Petroleum Contractors

- by Jeffrey Burke

- 12-1-2024

5.00 of 117 votesMobile Fuel Delivery in Florida: Convenience, Growth & Market Outlook Florida’s fast-paced markets and sprawling geography are fueling the shift toward mobile fuel delivery. Whether servicing fleets, job sites, or individual vehicles, on-demand fuel brought directly to you is reducing downtime, enhancing safety, and redefining modern fuel access. 1. Practical Convenience in Action Florida-based mobile fueling services like EzFill and Booster deliver gasoline or diesel directly to fleets—whether in parking lots, job sites, or residential areas. This means no more first thing lineup at fuel stations—vehicles stay productive and fueled on your schedule. ([turn0search1]) 2. Rapid Market Expansion The mobile fuel delivery sector is booming: globally valued at around USD 5.84 billion in 2025, it’s projected to nearly double to USD 11.93 billion by 2035, growing at a 7.4% CAGR. Demand is driven by operational efficiency, urban congestion, and digital platform adoption. ([turn0search15]) 3. Benefits for Florida Operators For commercial fleet managers, on-demand delivery replaces wasted hours at gas stations, cuts emissions from extra driving, and simplifies operations with predictable costs. As one user put it: “Never pump gas again.” ([turn0search1]) 4. Rapid Local Growth & Fleet Investment EzFill has aggressively expanded across Florida, tripling its fleet with 33 additional trucks to serve markets like Miami, Tampa, Orlando, and West Palm Beach—indicating strong demand for mobile fueling. ([turn0search13], [turn0search17]) 5. Supporting Emergency & Remote Needs Whether it’s job-site equipment, backup generators, or emergency response fleets, mobile fueling offers flexibility that fixed stations can't. With mobile infrastructure and cloud-enabled logistics, timely and targeted fueling is now possible anywhere. ([turn0search5], [turn0search7]) Why This Matters for Florida Given Florida’s congested roads, variable weather, and high seasonal demand, mobile fueling eliminates travel inefficiencies and improves resilience. For businesses, that means fewer interruptions and smoother operations year-round. Skip the station line and fuel on your terms—efficient, contactless, and tailored to your needs. Whether managing fleets or powering projects, mobile delivery can transform how you fuel. Let’s connect and explore how mobile fueling can power your peace of mind and productivity.

Why Use SPCI?

Southeastern Petroleum Contractors, Inc. © 2025

Powered By

Lakeland Marketing Pros